{"id":7017723756655,"title":"Darton MID Sleeves 87mm to 90mm MAX For Honda K24","handle":"darton-400-200-p","description":"\u003cstrong\u003eSpecifications:\u003c\/strong\u003e\u003cbr\u003eManufacturer: Darton\u003cbr\u003eReference Number: 400-200-P\u003cbr\u003e\u003cbr\u003e\u003cbr\u003e\u003cbr\u003eDarton designs’ manage and enhance water flow from block to head to promote stability of cooling and all sleeves are of the “Wet” design. The enhanced water flow in and around the flange area is possible because of ported water flow control engineering we call “Swirl Coolant Technology™”. This process begins with specific engineering models of respective cylinder head and combustion chamber designs and then we promote increased flow of water in those areas of the upper sleeve area subjected to the most heat. Heat is also dissipated through the use of ” Register Fins”™. There is a different engineering model for each engine and cylinder design. While heat is generally considered to translate into energy, high resident heat in the combustion chamber can lead to detonation, the single highest cause of engine failure in the high horsepower regimes.\u003cbr\u003e\u003cbr\u003e\n\nHigh RPM normally translates into efficient scavenging of airflow but during misfires or incomplete flame propagation, high cylinder pressures and temperatures are created. Our MID™ design compensates for this high resident heat soak condition. In the normal dry sleeve installation the cooling medium, water, must transfer heat absorption through block material and sleeves, which may be dissimilar metals. When dry sleeves are pressed in with interference fit, the materials interface is not perfect which further exacerbates heat transfer. This thermal conductivity is inefficient and as more heat is generated, the combustion process is compromised.\u003cbr\u003e\u003cbr\u003e\n\nEven in wet sleeve designs of the past, water is never efficiently processed or flowed between the block and head to provide for maximum heat dissipation in the combustion chamber. Inherent in open or closed deck engine blocks of cast iron or aluminum is a certain amount of water stagnation. This is like pouring water through a funnel, there is really no flow or velocity until the water exits the spigot. In the case of blocks and heads, the casting ports are designed for ease of casting not efficient flow. Now with Darton’s “MID”, Swirl Coolant Technology the cooling medium is ported and directed to significantly improve heat transfer where it is needed most, in the upper cylinder wall\/flange area.\u003cbr\u003e\u003cbr\u003e\n\nThe Darton MID™ Sleeve Kit is available for many series of 4, 6, and 8 cylinder import and domestic engines and provides for maximum bore sizes and boost potential. The benefits of our MID™ series kits are:\u003cbr\u003e\u003cbr\u003e\n\n Cast iron performance in an aluminum block\u003cbr\u003e\n Improved block integral strength\u003cbr\u003e\n Improved cooling\u003cbr\u003e\n Kits can be installed by your local machine shop\u003cbr\u003e\n “Wet sleeve” replaceability\u003cbr\u003e\n Full installation manual available on website\u003cbr\u003e\n Increased horsepower output potential\u003cbr\u003e\n High boost and horsepower potential\u003cbr\u003e\n Superior oil and compression control\u003cbr\u003e\n Superior cylinder sealing and ring wear\u003cbr\u003e\n Street or strip application\u003cbr\u003e\n Bulletproof Darton ductile iron\u003cbr\u003e\n 130,000-psi tensile strength\u003cbr\u003e\u003cbr\u003e\u003cbr\u003e\u003cbr\u003eBore: 3.415\u003cbr\u003eOD: 3.85\u003cbr\u003eWall: 0.217\u003cbr\u003eOAL: 5.8\u003cbr\u003eFlange Thickness: 0.5\u003cbr\u003eFlange diameter: 4.826\u003cbr\u003eApplication: 87mm to 90mm MAX\u003c!--split--\u003e\u003cstrong\u003eTaxes:\u003c\/strong\u003e\u003cbr\u003e\u003cbr\u003e\u003cstrong\u003eTVA \/ IVA \/ VAT: \u003c\/strong\u003eImport taxes and European Union (TVA \/ IVA \/ VAT) are included in our pricing excluding United Kingdom. Other countries such as Switzerland may have additional charges. For the rest of the countries, no other taxes will be charged to you during delivery!\u003cbr\u003e\u003cbr\u003e\u003chr\u003e\u003cstrong\u003eShipping: \u003c\/strong\u003e\u003cbr\u003e\u003cbr\u003eThis product will be shipped from our US Warehouse to our European Warehouse (Paris) and redistributed in Europe!Shipping via DHL within 3 to 7 days depending on location and local custom check. Allow two additional days for order processing.\u003cbr\u003eEvery Monday our team keeps you in the loop by sending out an \"estimated time of arrival\" email.\u003c!--split--\u003eThis part fits:\u003cbr\u003e\u003cbr\u003eK24A1 | 2400cc | DOHC | 16v | NA | I4,K24A2 | 2400cc | DOHC | 16v | NA | I4,K24A3 | 2400cc | DOHC | 16v | NA | I4,K24A4 | 2400cc | DOHC | 16v | NA | I4,K24A8 | 2400cc | DOHC | 16v | NA | I4,K24Y1 | 2400cc | DOHC | 16v | NA | I4,K24Y2 | 2400cc | DOHC | 16v | NA | I4,K24Z1 | 2400cc | DOHC | 16v | NA | I4,K24Z2 | 2400cc | DOHC | 16v | NA | I4,K24Z3 | 2400cc | DOHC | 16v | NA | I4,K24Z4 | 2400cc | DOHC | 16v | NA | I4,K24Z5 | 2400cc | DOHC | 16v | NA | I4,K24Z6 | 2400cc | DOHC | 16v | NA | I4,K24Z7 | 2400cc | DOHC | 16v | NA | I4\u003c!--split--\u003e","published_at":"2022-06-30T19:28:49+08:00","created_at":"2022-06-30T19:28:50+08:00","vendor":"Darton","type":"Build Your Block","tags":["build-your-block","darton"],"price":111840,"price_min":111840,"price_max":111840,"available":true,"price_varies":false,"compare_at_price":117720,"compare_at_price_min":117720,"compare_at_price_max":117720,"compare_at_price_varies":false,"variants":[{"id":40873379954799,"title":"Default Title","option1":"Default Title","option2":null,"option3":null,"sku":"400-200-P","requires_shipping":true,"taxable":true,"featured_image":null,"available":true,"name":"Darton MID Sleeves 87mm to 90mm MAX For Honda K24","public_title":null,"options":["Default Title"],"price":111840,"weight":8443,"compare_at_price":117720,"inventory_management":"shopify","barcode":null,"requires_selling_plan":false,"selling_plan_allocations":[]}],"images":["\/\/www.rzcreweurope.com\/cdn\/shop\/products\/Darton-MID-Sleeves-Kit-for-Honda-Accord-Prelude_219f59de-2aa9-4984-9600-b51da52540e5.jpg?v=1656588530"],"featured_image":"\/\/www.rzcreweurope.com\/cdn\/shop\/products\/Darton-MID-Sleeves-Kit-for-Honda-Accord-Prelude_219f59de-2aa9-4984-9600-b51da52540e5.jpg?v=1656588530","options":["Title"],"media":[{"alt":"Darton - 400-200-P","id":23581402038383,"position":1,"preview_image":{"aspect_ratio":1.25,"height":800,"width":1000,"src":"\/\/www.rzcreweurope.com\/cdn\/shop\/products\/Darton-MID-Sleeves-Kit-for-Honda-Accord-Prelude_219f59de-2aa9-4984-9600-b51da52540e5.jpg?v=1656588530"},"aspect_ratio":1.25,"height":800,"media_type":"image","src":"\/\/www.rzcreweurope.com\/cdn\/shop\/products\/Darton-MID-Sleeves-Kit-for-Honda-Accord-Prelude_219f59de-2aa9-4984-9600-b51da52540e5.jpg?v=1656588530","width":1000}],"requires_selling_plan":false,"selling_plan_groups":[],"content":"\u003cstrong\u003eSpecifications:\u003c\/strong\u003e\u003cbr\u003eManufacturer: Darton\u003cbr\u003eReference Number: 400-200-P\u003cbr\u003e\u003cbr\u003e\u003cbr\u003e\u003cbr\u003eDarton designs’ manage and enhance water flow from block to head to promote stability of cooling and all sleeves are of the “Wet” design. The enhanced water flow in and around the flange area is possible because of ported water flow control engineering we call “Swirl Coolant Technology™”. This process begins with specific engineering models of respective cylinder head and combustion chamber designs and then we promote increased flow of water in those areas of the upper sleeve area subjected to the most heat. Heat is also dissipated through the use of ” Register Fins”™. There is a different engineering model for each engine and cylinder design. While heat is generally considered to translate into energy, high resident heat in the combustion chamber can lead to detonation, the single highest cause of engine failure in the high horsepower regimes.\u003cbr\u003e\u003cbr\u003e\n\nHigh RPM normally translates into efficient scavenging of airflow but during misfires or incomplete flame propagation, high cylinder pressures and temperatures are created. Our MID™ design compensates for this high resident heat soak condition. In the normal dry sleeve installation the cooling medium, water, must transfer heat absorption through block material and sleeves, which may be dissimilar metals. When dry sleeves are pressed in with interference fit, the materials interface is not perfect which further exacerbates heat transfer. This thermal conductivity is inefficient and as more heat is generated, the combustion process is compromised.\u003cbr\u003e\u003cbr\u003e\n\nEven in wet sleeve designs of the past, water is never efficiently processed or flowed between the block and head to provide for maximum heat dissipation in the combustion chamber. Inherent in open or closed deck engine blocks of cast iron or aluminum is a certain amount of water stagnation. This is like pouring water through a funnel, there is really no flow or velocity until the water exits the spigot. In the case of blocks and heads, the casting ports are designed for ease of casting not efficient flow. Now with Darton’s “MID”, Swirl Coolant Technology the cooling medium is ported and directed to significantly improve heat transfer where it is needed most, in the upper cylinder wall\/flange area.\u003cbr\u003e\u003cbr\u003e\n\nThe Darton MID™ Sleeve Kit is available for many series of 4, 6, and 8 cylinder import and domestic engines and provides for maximum bore sizes and boost potential. The benefits of our MID™ series kits are:\u003cbr\u003e\u003cbr\u003e\n\n Cast iron performance in an aluminum block\u003cbr\u003e\n Improved block integral strength\u003cbr\u003e\n Improved cooling\u003cbr\u003e\n Kits can be installed by your local machine shop\u003cbr\u003e\n “Wet sleeve” replaceability\u003cbr\u003e\n Full installation manual available on website\u003cbr\u003e\n Increased horsepower output potential\u003cbr\u003e\n High boost and horsepower potential\u003cbr\u003e\n Superior oil and compression control\u003cbr\u003e\n Superior cylinder sealing and ring wear\u003cbr\u003e\n Street or strip application\u003cbr\u003e\n Bulletproof Darton ductile iron\u003cbr\u003e\n 130,000-psi tensile strength\u003cbr\u003e\u003cbr\u003e\u003cbr\u003e\u003cbr\u003eBore: 3.415\u003cbr\u003eOD: 3.85\u003cbr\u003eWall: 0.217\u003cbr\u003eOAL: 5.8\u003cbr\u003eFlange Thickness: 0.5\u003cbr\u003eFlange diameter: 4.826\u003cbr\u003eApplication: 87mm to 90mm MAX\u003c!--split--\u003e\u003cstrong\u003eTaxes:\u003c\/strong\u003e\u003cbr\u003e\u003cbr\u003e\u003cstrong\u003eTVA \/ IVA \/ VAT: \u003c\/strong\u003eImport taxes and European Union (TVA \/ IVA \/ VAT) are included in our pricing excluding United Kingdom. Other countries such as Switzerland may have additional charges. For the rest of the countries, no other taxes will be charged to you during delivery!\u003cbr\u003e\u003cbr\u003e\u003chr\u003e\u003cstrong\u003eShipping: \u003c\/strong\u003e\u003cbr\u003e\u003cbr\u003eThis product will be shipped from our US Warehouse to our European Warehouse (Paris) and redistributed in Europe!Shipping via DHL within 3 to 7 days depending on location and local custom check. Allow two additional days for order processing.\u003cbr\u003eEvery Monday our team keeps you in the loop by sending out an \"estimated time of arrival\" email.\u003c!--split--\u003eThis part fits:\u003cbr\u003e\u003cbr\u003eK24A1 | 2400cc | DOHC | 16v | NA | I4,K24A2 | 2400cc | DOHC | 16v | NA | I4,K24A3 | 2400cc | DOHC | 16v | NA | I4,K24A4 | 2400cc | DOHC | 16v | NA | I4,K24A8 | 2400cc | DOHC | 16v | NA | I4,K24Y1 | 2400cc | DOHC | 16v | NA | I4,K24Y2 | 2400cc | DOHC | 16v | NA | I4,K24Z1 | 2400cc | DOHC | 16v | NA | I4,K24Z2 | 2400cc | DOHC | 16v | NA | I4,K24Z3 | 2400cc | DOHC | 16v | NA | I4,K24Z4 | 2400cc | DOHC | 16v | NA | I4,K24Z5 | 2400cc | DOHC | 16v | NA | I4,K24Z6 | 2400cc | DOHC | 16v | NA | I4,K24Z7 | 2400cc | DOHC | 16v | NA | I4\u003c!--split--\u003e"}

Darton MID Sleeves 87mm to 90mm MAX For Honda K24

Specifications:

Manufacturer: Darton

Reference Number: 400-200-P

Darton designs’ manage and enhance water flow from block to head to promote stability of cooling and all sleeves are of the “Wet” design. The enhanced water flow in and around the flange area is possible because of ported water flow control engineering we call “Swirl Coolant Technology™”. This process begins with specific engineering models of respective cylinder head and combustion chamber designs and then we promote increased flow of water in those areas of the upper sleeve area subjected to the most heat. Heat is also dissipated through the use of ” Register Fins”™. There is a different engineering model for each engine and cylinder design. While heat is generally considered to translate into energy, high resident heat in the combustion chamber can lead to detonation, the single highest cause of engine failure in the high horsepower regimes.

High RPM normally translates into efficient scavenging of airflow but during misfires or incomplete flame propagation, high cylinder pressures and temperatures are created. Our MID™ design compensates for this high resident heat soak condition. In the normal dry sleeve installation the cooling medium, water, must transfer heat absorption through block material and sleeves, which may be dissimilar metals. When dry sleeves are pressed in with interference fit, the materials interface is not perfect which further exacerbates heat transfer. This thermal conductivity is inefficient and as more heat is generated, the combustion process is compromised.

Even in wet sleeve designs of the past, water is never efficiently processed or flowed between the block and head to provide for maximum heat dissipation in the combustion chamber. Inherent in open or closed deck engine blocks of cast iron or aluminum is a certain amount of water stagnation. This is like pouring water through a funnel, there is really no flow or velocity until the water exits the spigot. In the case of blocks and heads, the casting ports are designed for ease of casting not efficient flow. Now with Darton’s “MID”, Swirl Coolant Technology the cooling medium is ported and directed to significantly improve heat transfer where it is needed most, in the upper cylinder wall/flange area.

The Darton MID™ Sleeve Kit is available for many series of 4, 6, and 8 cylinder import and domestic engines and provides for maximum bore sizes and boost potential. The benefits of our MID™ series kits are:

Cast iron performance in an aluminum block

Improved block integral strength

Improved cooling

Kits can be installed by your local machine shop

“Wet sleeve” replaceability

Full installation manual available on website

Increased horsepower output potential

High boost and horsepower potential

Superior oil and compression control

Superior cylinder sealing and ring wear

Street or strip application

Bulletproof Darton ductile iron

130,000-psi tensile strength

Bore: 3.415

OD: 3.85

Wall: 0.217

OAL: 5.8

Flange Thickness: 0.5

Flange diameter: 4.826

Application: 87mm to 90mm MAX

Manufacturer: Darton

Reference Number: 400-200-P

Darton designs’ manage and enhance water flow from block to head to promote stability of cooling and all sleeves are of the “Wet” design. The enhanced water flow in and around the flange area is possible because of ported water flow control engineering we call “Swirl Coolant Technology™”. This process begins with specific engineering models of respective cylinder head and combustion chamber designs and then we promote increased flow of water in those areas of the upper sleeve area subjected to the most heat. Heat is also dissipated through the use of ” Register Fins”™. There is a different engineering model for each engine and cylinder design. While heat is generally considered to translate into energy, high resident heat in the combustion chamber can lead to detonation, the single highest cause of engine failure in the high horsepower regimes.

High RPM normally translates into efficient scavenging of airflow but during misfires or incomplete flame propagation, high cylinder pressures and temperatures are created. Our MID™ design compensates for this high resident heat soak condition. In the normal dry sleeve installation the cooling medium, water, must transfer heat absorption through block material and sleeves, which may be dissimilar metals. When dry sleeves are pressed in with interference fit, the materials interface is not perfect which further exacerbates heat transfer. This thermal conductivity is inefficient and as more heat is generated, the combustion process is compromised.

Even in wet sleeve designs of the past, water is never efficiently processed or flowed between the block and head to provide for maximum heat dissipation in the combustion chamber. Inherent in open or closed deck engine blocks of cast iron or aluminum is a certain amount of water stagnation. This is like pouring water through a funnel, there is really no flow or velocity until the water exits the spigot. In the case of blocks and heads, the casting ports are designed for ease of casting not efficient flow. Now with Darton’s “MID”, Swirl Coolant Technology the cooling medium is ported and directed to significantly improve heat transfer where it is needed most, in the upper cylinder wall/flange area.

The Darton MID™ Sleeve Kit is available for many series of 4, 6, and 8 cylinder import and domestic engines and provides for maximum bore sizes and boost potential. The benefits of our MID™ series kits are:

Cast iron performance in an aluminum block

Improved block integral strength

Improved cooling

Kits can be installed by your local machine shop

“Wet sleeve” replaceability

Full installation manual available on website

Increased horsepower output potential

High boost and horsepower potential

Superior oil and compression control

Superior cylinder sealing and ring wear

Street or strip application

Bulletproof Darton ductile iron

130,000-psi tensile strength

Bore: 3.415

OD: 3.85

Wall: 0.217

OAL: 5.8

Flange Thickness: 0.5

Flange diameter: 4.826

Application: 87mm to 90mm MAX

Taxes:

TVA / IVA / VAT: All import taxes (TVA / IVA / VAT) are included in our pricing. No other taxes will be charged to you during delivery!

TVA / IVA / VAT: All import taxes (TVA / IVA / VAT) are included in our pricing. No other taxes will be charged to you during delivery!

This part fits:

K24A1 | 2400cc | DOHC | 16v | NA | I4,K24A2 | 2400cc | DOHC | 16v | NA | I4,K24A3 | 2400cc | DOHC | 16v | NA | I4,K24A4 | 2400cc | DOHC | 16v | NA | I4,K24A8 | 2400cc | DOHC | 16v | NA | I4,K24Y1 | 2400cc | DOHC | 16v | NA | I4,K24Y2 | 2400cc | DOHC | 16v | NA | I4,K24Z1 | 2400cc | DOHC | 16v | NA | I4,K24Z2 | 2400cc | DOHC | 16v | NA | I4,K24Z3 | 2400cc | DOHC | 16v | NA | I4,K24Z4 | 2400cc | DOHC | 16v | NA | I4,K24Z5 | 2400cc | DOHC | 16v | NA | I4,K24Z6 | 2400cc | DOHC | 16v | NA | I4,K24Z7 | 2400cc | DOHC | 16v | NA | I4

K24A1 | 2400cc | DOHC | 16v | NA | I4,K24A2 | 2400cc | DOHC | 16v | NA | I4,K24A3 | 2400cc | DOHC | 16v | NA | I4,K24A4 | 2400cc | DOHC | 16v | NA | I4,K24A8 | 2400cc | DOHC | 16v | NA | I4,K24Y1 | 2400cc | DOHC | 16v | NA | I4,K24Y2 | 2400cc | DOHC | 16v | NA | I4,K24Z1 | 2400cc | DOHC | 16v | NA | I4,K24Z2 | 2400cc | DOHC | 16v | NA | I4,K24Z3 | 2400cc | DOHC | 16v | NA | I4,K24Z4 | 2400cc | DOHC | 16v | NA | I4,K24Z5 | 2400cc | DOHC | 16v | NA | I4,K24Z6 | 2400cc | DOHC | 16v | NA | I4,K24Z7 | 2400cc | DOHC | 16v | NA | I4

Related Products

Genuine Honda Parts - Type R Oil Pump - Honda - K series

€283,00 €235,90

Rzcrew Racing - Billet Block Guard - Suzuki M16A

€150,00 €96,20

Rzcrew Racing - Billet Block Guard - Toyota 1NZ-FE

€150,00 €96,20

Genuine Honda Parts - Oil Pump - Honda F20/22C

€446,00 €372,30

ARP - Head Stud Kit Suzuki Swift M15A/M16A/M18A 271-4301

€372,00 €354,00

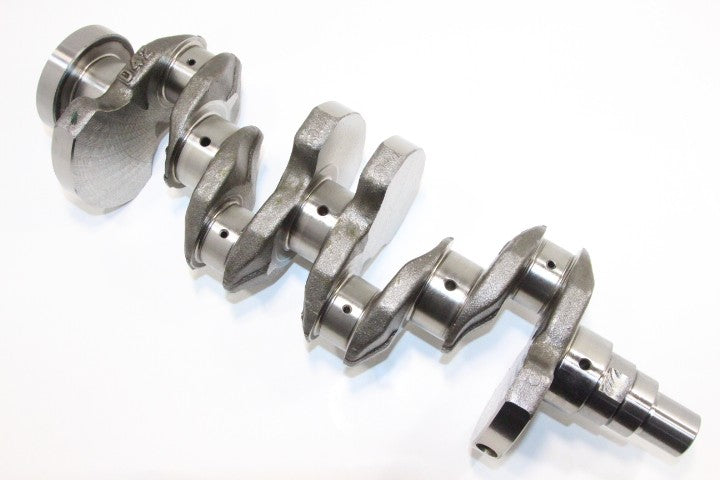

OEM Nissan - Crankshaft - Nissan CA18DET

€1.667,00 €1.582,10

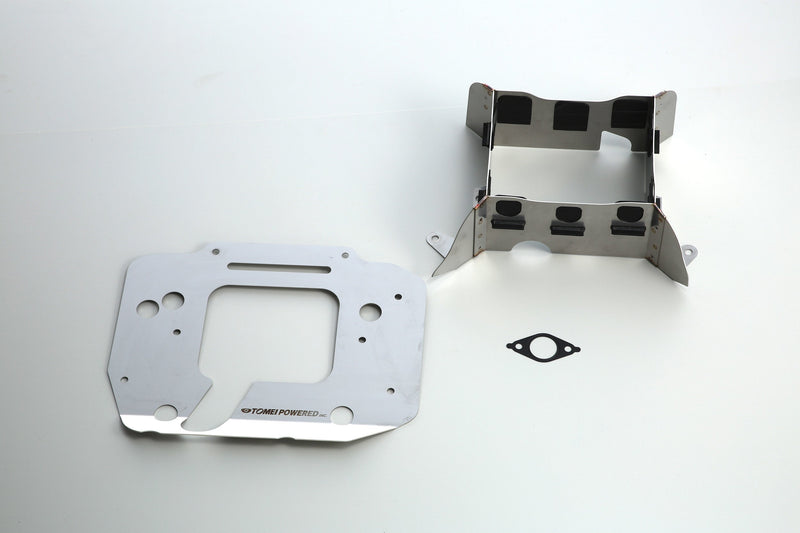

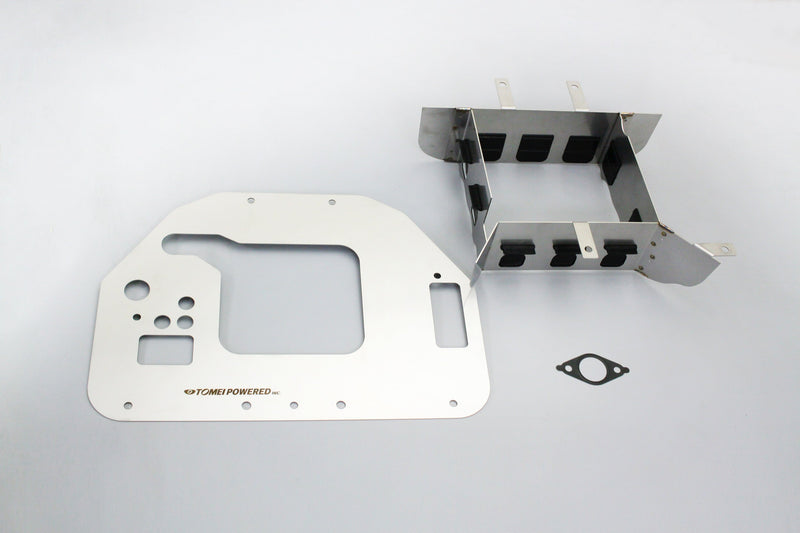

Tomei - Oil Pan Baffle Plate Type R - Toyota 1/2JZ

€295,00 €241,50

Tomei - Oil Pan Baffle Plate Type F2 - Toyota 1/2JZ

€295,00 €241,50

Rzcrew Racing - Billet Block Guard - Honda K24

€150,00 €96,20

Toda Racing - Lightweight Idler Pulley for FN2 - Honda - K20A

€194,00 €174,70