{"id":9733865799955,"title":"Spoon - Blue Printed Engine - Honda K20C1","handle":"spoon-blue-printed-engine-honda-k20c1-10000-fk8-c00-10000-fk8-c00","description":"\u003cstrong\u003eSpecifications:\u003c\/strong\u003e\u003cbr\u003eManufacturer: Spoon\u003cbr\u003eReference Number: 10000-FK8-C00\u003cbr\u003e\u003cbr\u003e\u003cbr\u003e\u003cbr\u003eENGINE COMPLETE is assembled using all new genuine Honda parts.\nThe edges of the cylinder block and cylinder head are all deburred to avoid stress concentration and to prevent metal pieces generated during the manufacturer's manufacturing process from falling into the engine.\nAdditionally, the assembled weight of the moving parts such as the piston, piston pin, and connecting rod is kept within 0.02g for each cylinder.\nThe total weight of these moving parts is approximately 1,100g (K20C), and the difference between cylinders is 0.002%.\nThe allowable weight difference for conventional Honda Type R engines is 0.2%, so we are pursuing accuracy that is 100 times greater.\nEqualizing the weight of moving parts reduces unbalance and reduces vibration, allowing the rotation to rise smoothly and giving you a pleasant experience that does not appear in numerical values ??such as the power curve.\u003cbr\u003e\u003cbr\u003e\n\nFurthermore, an important point in engine assembly is clearance management.\nThe engine combines different materials such as aluminum and steel to achieve both strength and weight reduction.\nAn iron cylinder sleeve is cast into an aluminum cylinder block, and an aluminum piston is installed. In addition, the crankshaft, camshaft, intake and exhaust valves are made of iron and are assembled into an aluminum cylinder block and cylinder head.\nAluminum and steel have different coefficients of thermal expansion, so the clearance changes as the temperature changes.\nFor this reason, the clean room where engines are assembled uses air conditioning to equalize the room temperature, keep component temperatures constant throughout the year, and enable precise clearance control during assembly.\n\u003cbr\u003e\u003cbr\u003e\nExperience the true nature of Honda engines, where highly-precision parts are assembled by skilled mechanics in a properly controlled environment.\u003cbr\u003e\n\nThe ENGINE COMPLETE package is built entirely with brand new OE parts from Honda. Before assembly, all metal burrs are removed from the cylinder block and cylinder head to avoid possible stress concentration and to avoid engine damage from contamination.\u003cbr\u003e\nThe piston, piston pin and all moving parts of the conrod are carefully weighed and balanced within 0.02g of tolerance on each cylinder.\nThe total weight of the moving parts is approximately 1,100g (K20C) hence tolerance of 0.02g translates to managing the weight difference within 0.002%.\nStock Honda Type R engines are built with a tolerance of 0.2%. We've set our bar 100 times higher.\nPrecise weight management of moving parts in an engine helps to decrease minute vibrations, allowing the engine to rev smoothly. The effect may not be visible on a power curve, but it definitely reflects on driving feel.\n\u003cbr\u003e\u003cbr\u003e\nAnother critical factor of building an engine is clearance management.\nModern engines are made up of different materials such as aluminum and steel in order to balance durability and weight saving.\nCylinder sleeves made of steel is cast molded into an aluminum cylinder block and combined with pistons made from aluminum. Crankshaft, camshaft and intake\/exhaust valves are made of steel, assembled to cylinder blocks and cylinder heads made of aluminum.\u003cbr\u003e\nSince the coefficient of thermal expansion are different between aluminum and steel, clearance deviates according to temperature fluctuation.\u003cbr\u003e\nAt SPOON SPORTS, we take pride in assembling all our engines in a cleanroom, temperature controlled to maintain an environment for optimum clearance management during assembly.\u003cbr\u003e\u003cbr\u003e\n\nPrecision components are assembled in a constant environment by our skilled engine builders. We look forward to delivering the true performance of the Honda engine to our customers!\u003cbr\u003e\u003c!--split--\u003e\u003cstrong\u003eTaxes:\u003c\/strong\u003e\u003cbr\u003e\u003cbr\u003e\u003cstrong\u003eSingapore and Malaysia: \u003c\/strong\u003eAll import taxes are included in our pricing.\u003cbr\u003e\u003cbr\u003e\u003cstrong\u003eEuropean Tva, Iva: \u003c\/strong\u003eTaxes will be calculated during checkout at our company import rate. No additional charges will be added by your local authority.\u003cbr\u003e\u003cbr\u003e\u003cstrong\u003eUSA:\u003c\/strong\u003e If this product is shipped from our US warehouse then taxes are included. Otherwise, please refer to the rest of the world paragragh.\u003cbr\u003e\u003cbr\u003e\u003cstrong\u003eRest of the World:\u003c\/strong\u003e Other countries may have to pay their local import tax depending on your country's regulations.\u003chr\u003e\u003cstrong\u003eShipping: \u003c\/strong\u003e\u003cbr\u003e\u003cbr\u003eThis product will be shipped from our Japanese Warehouse to any global location. Shipping via DHL within 3 to 7 days depending on location and local custom check. Allow two additional days for order processing.\u003cbr\u003eEvery Monday our team keeps you in the loop by sending out an \"estimated time of arrival\" email.\u003c!--split--\u003eThis part fits:\u003cbr\u003e\u003cbr\u003eK20C1 | 2000cc | DOHC | 16v | TC | I4\u003c!--split--\u003e","published_at":"2024-11-12T12:16:20+08:00","created_at":"2024-11-12T12:16:22+08:00","vendor":"Spoon","type":"Build Your Block,Build Your Head","tags":["build-your-block-build-your-head","honda","jp1","K20C1","k20c1-2000cc-dohc-16v-tc-i4","spoon","ws14"],"price":1535350,"price_min":1535350,"price_max":1535350,"available":true,"price_varies":false,"compare_at_price":1498500,"compare_at_price_min":1498500,"compare_at_price_max":1498500,"compare_at_price_varies":false,"variants":[{"id":50024135196947,"title":"Default Title","option1":"Default Title","option2":null,"option3":null,"sku":"10000-FK8-C00","requires_shipping":true,"taxable":true,"featured_image":null,"available":true,"name":"Spoon - Blue Printed Engine - Honda K20C1","public_title":null,"options":["Default Title"],"price":1535350,"weight":100000,"compare_at_price":1498500,"inventory_management":"shopify","barcode":null,"requires_selling_plan":false,"selling_plan_allocations":[]}],"images":["\/\/www.rzcreweurope.com\/cdn\/shop\/files\/10000-FK8-C00_ad9e7355-452e-4e80-a116-a8503fb9910e.jpg?v=1747648791"],"featured_image":"\/\/www.rzcreweurope.com\/cdn\/shop\/files\/10000-FK8-C00_ad9e7355-452e-4e80-a116-a8503fb9910e.jpg?v=1747648791","options":["Title"],"media":[{"alt":"Spoon - Blue Printed Engine - Honda K20C1 - 10000-FK8-C00 - 10000-FK8-C00","id":41455489515795,"position":1,"preview_image":{"aspect_ratio":1.501,"height":853,"width":1280,"src":"\/\/www.rzcreweurope.com\/cdn\/shop\/files\/10000-FK8-C00_ad9e7355-452e-4e80-a116-a8503fb9910e.jpg?v=1747648791"},"aspect_ratio":1.501,"height":853,"media_type":"image","src":"\/\/www.rzcreweurope.com\/cdn\/shop\/files\/10000-FK8-C00_ad9e7355-452e-4e80-a116-a8503fb9910e.jpg?v=1747648791","width":1280}],"requires_selling_plan":false,"selling_plan_groups":[],"content":"\u003cstrong\u003eSpecifications:\u003c\/strong\u003e\u003cbr\u003eManufacturer: Spoon\u003cbr\u003eReference Number: 10000-FK8-C00\u003cbr\u003e\u003cbr\u003e\u003cbr\u003e\u003cbr\u003eENGINE COMPLETE is assembled using all new genuine Honda parts.\nThe edges of the cylinder block and cylinder head are all deburred to avoid stress concentration and to prevent metal pieces generated during the manufacturer's manufacturing process from falling into the engine.\nAdditionally, the assembled weight of the moving parts such as the piston, piston pin, and connecting rod is kept within 0.02g for each cylinder.\nThe total weight of these moving parts is approximately 1,100g (K20C), and the difference between cylinders is 0.002%.\nThe allowable weight difference for conventional Honda Type R engines is 0.2%, so we are pursuing accuracy that is 100 times greater.\nEqualizing the weight of moving parts reduces unbalance and reduces vibration, allowing the rotation to rise smoothly and giving you a pleasant experience that does not appear in numerical values ??such as the power curve.\u003cbr\u003e\u003cbr\u003e\n\nFurthermore, an important point in engine assembly is clearance management.\nThe engine combines different materials such as aluminum and steel to achieve both strength and weight reduction.\nAn iron cylinder sleeve is cast into an aluminum cylinder block, and an aluminum piston is installed. In addition, the crankshaft, camshaft, intake and exhaust valves are made of iron and are assembled into an aluminum cylinder block and cylinder head.\nAluminum and steel have different coefficients of thermal expansion, so the clearance changes as the temperature changes.\nFor this reason, the clean room where engines are assembled uses air conditioning to equalize the room temperature, keep component temperatures constant throughout the year, and enable precise clearance control during assembly.\n\u003cbr\u003e\u003cbr\u003e\nExperience the true nature of Honda engines, where highly-precision parts are assembled by skilled mechanics in a properly controlled environment.\u003cbr\u003e\n\nThe ENGINE COMPLETE package is built entirely with brand new OE parts from Honda. Before assembly, all metal burrs are removed from the cylinder block and cylinder head to avoid possible stress concentration and to avoid engine damage from contamination.\u003cbr\u003e\nThe piston, piston pin and all moving parts of the conrod are carefully weighed and balanced within 0.02g of tolerance on each cylinder.\nThe total weight of the moving parts is approximately 1,100g (K20C) hence tolerance of 0.02g translates to managing the weight difference within 0.002%.\nStock Honda Type R engines are built with a tolerance of 0.2%. We've set our bar 100 times higher.\nPrecise weight management of moving parts in an engine helps to decrease minute vibrations, allowing the engine to rev smoothly. The effect may not be visible on a power curve, but it definitely reflects on driving feel.\n\u003cbr\u003e\u003cbr\u003e\nAnother critical factor of building an engine is clearance management.\nModern engines are made up of different materials such as aluminum and steel in order to balance durability and weight saving.\nCylinder sleeves made of steel is cast molded into an aluminum cylinder block and combined with pistons made from aluminum. Crankshaft, camshaft and intake\/exhaust valves are made of steel, assembled to cylinder blocks and cylinder heads made of aluminum.\u003cbr\u003e\nSince the coefficient of thermal expansion are different between aluminum and steel, clearance deviates according to temperature fluctuation.\u003cbr\u003e\nAt SPOON SPORTS, we take pride in assembling all our engines in a cleanroom, temperature controlled to maintain an environment for optimum clearance management during assembly.\u003cbr\u003e\u003cbr\u003e\n\nPrecision components are assembled in a constant environment by our skilled engine builders. We look forward to delivering the true performance of the Honda engine to our customers!\u003cbr\u003e\u003c!--split--\u003e\u003cstrong\u003eTaxes:\u003c\/strong\u003e\u003cbr\u003e\u003cbr\u003e\u003cstrong\u003eSingapore and Malaysia: \u003c\/strong\u003eAll import taxes are included in our pricing.\u003cbr\u003e\u003cbr\u003e\u003cstrong\u003eEuropean Tva, Iva: \u003c\/strong\u003eTaxes will be calculated during checkout at our company import rate. No additional charges will be added by your local authority.\u003cbr\u003e\u003cbr\u003e\u003cstrong\u003eUSA:\u003c\/strong\u003e If this product is shipped from our US warehouse then taxes are included. Otherwise, please refer to the rest of the world paragragh.\u003cbr\u003e\u003cbr\u003e\u003cstrong\u003eRest of the World:\u003c\/strong\u003e Other countries may have to pay their local import tax depending on your country's regulations.\u003chr\u003e\u003cstrong\u003eShipping: \u003c\/strong\u003e\u003cbr\u003e\u003cbr\u003eThis product will be shipped from our Japanese Warehouse to any global location. Shipping via DHL within 3 to 7 days depending on location and local custom check. Allow two additional days for order processing.\u003cbr\u003eEvery Monday our team keeps you in the loop by sending out an \"estimated time of arrival\" email.\u003c!--split--\u003eThis part fits:\u003cbr\u003e\u003cbr\u003eK20C1 | 2000cc | DOHC | 16v | TC | I4\u003c!--split--\u003e"}

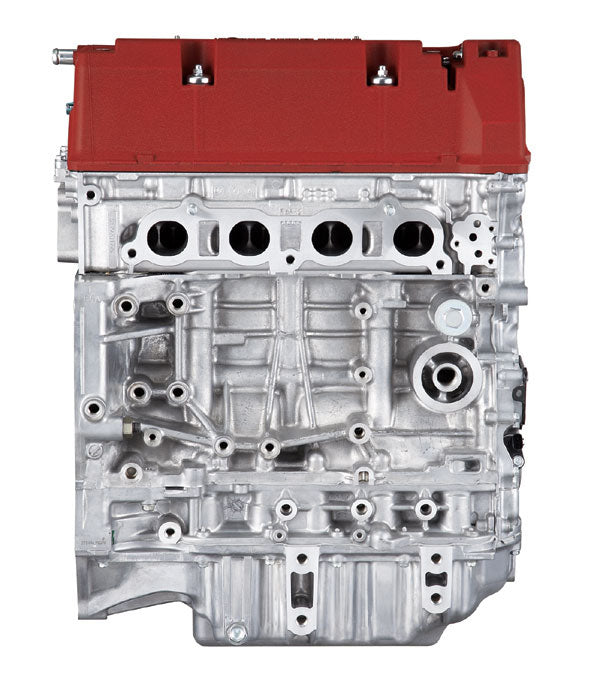

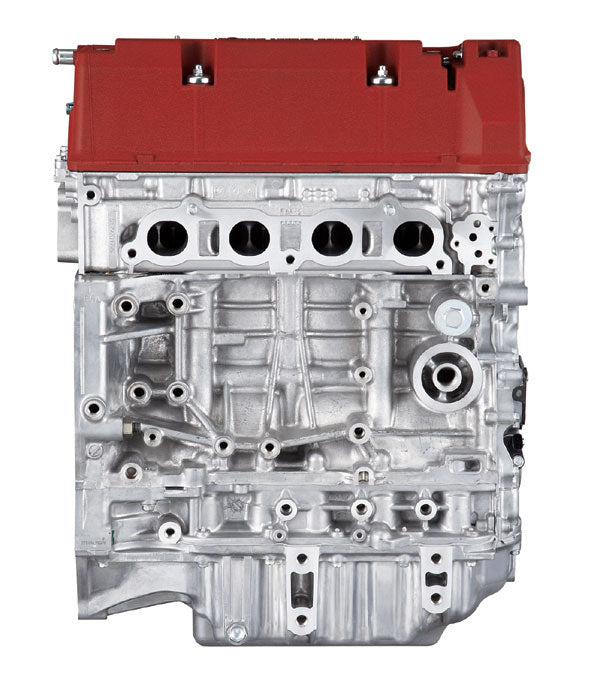

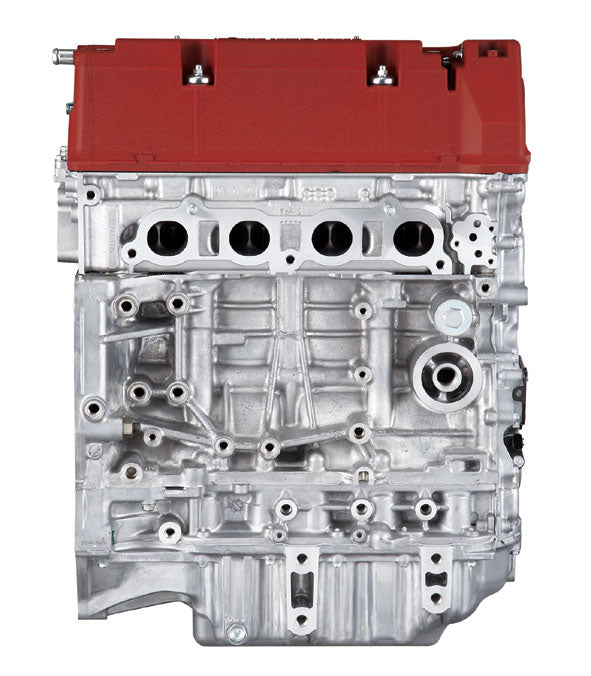

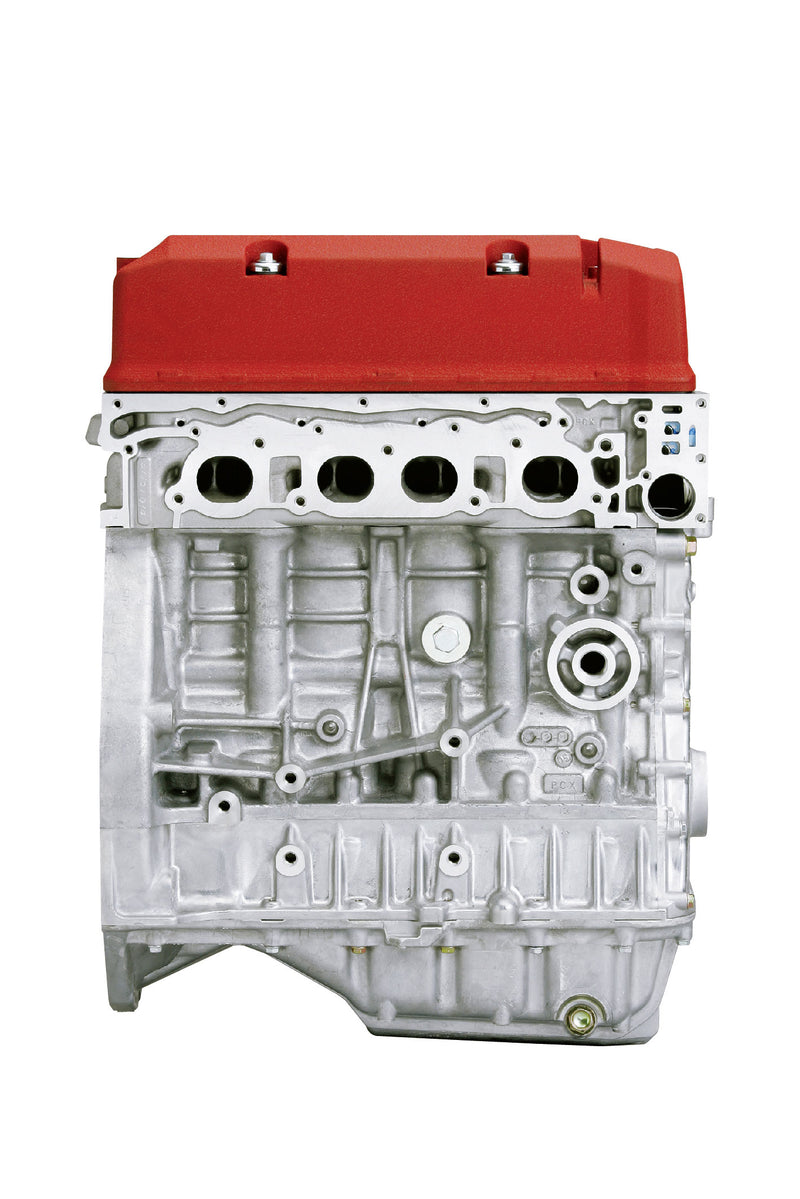

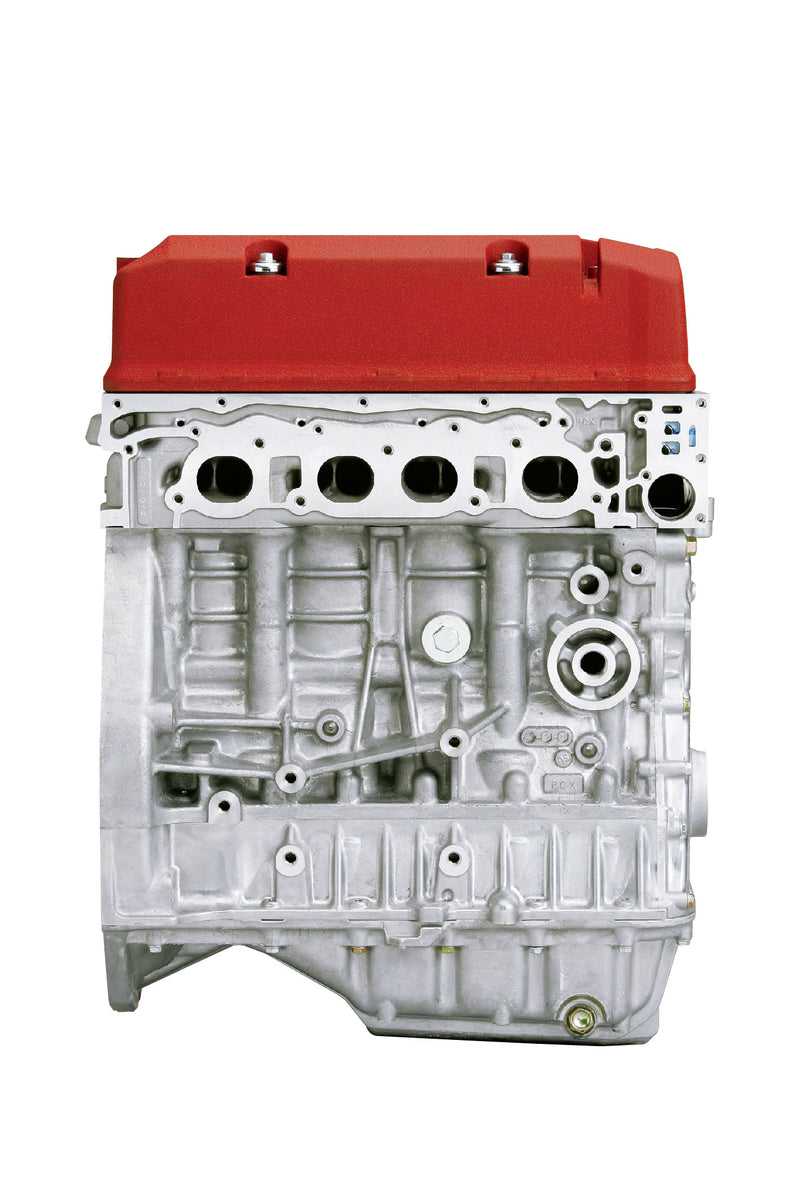

Spoon - Blue Printed Engine - Honda K20C1

Specifications:

Manufacturer: Spoon

Reference Number: 10000-FK8-C00

ENGINE COMPLETE is assembled using all new genuine Honda parts. The edges of the cylinder block and cylinder head are all deburred to avoid stress concentration and to prevent metal pieces generated during the manufacturer's manufacturing process from falling into the engine. Additionally, the assembled weight of the moving parts such as the piston, piston pin, and connecting rod is kept within 0.02g for each cylinder. The total weight of these moving parts is approximately 1,100g (K20C), and the difference between cylinders is 0.002%. The allowable weight difference for conventional Honda Type R engines is 0.2%, so we are pursuing accuracy that is 100 times greater. Equalizing the weight of moving parts reduces unbalance and reduces vibration, allowing the rotation to rise smoothly and giving you a pleasant experience that does not appear in numerical values ??such as the power curve.

Furthermore, an important point in engine assembly is clearance management. The engine combines different materials such as aluminum and steel to achieve both strength and weight reduction. An iron cylinder sleeve is cast into an aluminum cylinder block, and an aluminum piston is installed. In addition, the crankshaft, camshaft, intake and exhaust valves are made of iron and are assembled into an aluminum cylinder block and cylinder head. Aluminum and steel have different coefficients of thermal expansion, so the clearance changes as the temperature changes. For this reason, the clean room where engines are assembled uses air conditioning to equalize the room temperature, keep component temperatures constant throughout the year, and enable precise clearance control during assembly.

Experience the true nature of Honda engines, where highly-precision parts are assembled by skilled mechanics in a properly controlled environment.

The ENGINE COMPLETE package is built entirely with brand new OE parts from Honda. Before assembly, all metal burrs are removed from the cylinder block and cylinder head to avoid possible stress concentration and to avoid engine damage from contamination.

The piston, piston pin and all moving parts of the conrod are carefully weighed and balanced within 0.02g of tolerance on each cylinder. The total weight of the moving parts is approximately 1,100g (K20C) hence tolerance of 0.02g translates to managing the weight difference within 0.002%. Stock Honda Type R engines are built with a tolerance of 0.2%. We've set our bar 100 times higher. Precise weight management of moving parts in an engine helps to decrease minute vibrations, allowing the engine to rev smoothly. The effect may not be visible on a power curve, but it definitely reflects on driving feel.

Another critical factor of building an engine is clearance management. Modern engines are made up of different materials such as aluminum and steel in order to balance durability and weight saving. Cylinder sleeves made of steel is cast molded into an aluminum cylinder block and combined with pistons made from aluminum. Crankshaft, camshaft and intake/exhaust valves are made of steel, assembled to cylinder blocks and cylinder heads made of aluminum.

Since the coefficient of thermal expansion are different between aluminum and steel, clearance deviates according to temperature fluctuation.

At SPOON SPORTS, we take pride in assembling all our engines in a cleanroom, temperature controlled to maintain an environment for optimum clearance management during assembly.

Precision components are assembled in a constant environment by our skilled engine builders. We look forward to delivering the true performance of the Honda engine to our customers!

Manufacturer: Spoon

Reference Number: 10000-FK8-C00

ENGINE COMPLETE is assembled using all new genuine Honda parts. The edges of the cylinder block and cylinder head are all deburred to avoid stress concentration and to prevent metal pieces generated during the manufacturer's manufacturing process from falling into the engine. Additionally, the assembled weight of the moving parts such as the piston, piston pin, and connecting rod is kept within 0.02g for each cylinder. The total weight of these moving parts is approximately 1,100g (K20C), and the difference between cylinders is 0.002%. The allowable weight difference for conventional Honda Type R engines is 0.2%, so we are pursuing accuracy that is 100 times greater. Equalizing the weight of moving parts reduces unbalance and reduces vibration, allowing the rotation to rise smoothly and giving you a pleasant experience that does not appear in numerical values ??such as the power curve.

Furthermore, an important point in engine assembly is clearance management. The engine combines different materials such as aluminum and steel to achieve both strength and weight reduction. An iron cylinder sleeve is cast into an aluminum cylinder block, and an aluminum piston is installed. In addition, the crankshaft, camshaft, intake and exhaust valves are made of iron and are assembled into an aluminum cylinder block and cylinder head. Aluminum and steel have different coefficients of thermal expansion, so the clearance changes as the temperature changes. For this reason, the clean room where engines are assembled uses air conditioning to equalize the room temperature, keep component temperatures constant throughout the year, and enable precise clearance control during assembly.

Experience the true nature of Honda engines, where highly-precision parts are assembled by skilled mechanics in a properly controlled environment.

The ENGINE COMPLETE package is built entirely with brand new OE parts from Honda. Before assembly, all metal burrs are removed from the cylinder block and cylinder head to avoid possible stress concentration and to avoid engine damage from contamination.

The piston, piston pin and all moving parts of the conrod are carefully weighed and balanced within 0.02g of tolerance on each cylinder. The total weight of the moving parts is approximately 1,100g (K20C) hence tolerance of 0.02g translates to managing the weight difference within 0.002%. Stock Honda Type R engines are built with a tolerance of 0.2%. We've set our bar 100 times higher. Precise weight management of moving parts in an engine helps to decrease minute vibrations, allowing the engine to rev smoothly. The effect may not be visible on a power curve, but it definitely reflects on driving feel.

Another critical factor of building an engine is clearance management. Modern engines are made up of different materials such as aluminum and steel in order to balance durability and weight saving. Cylinder sleeves made of steel is cast molded into an aluminum cylinder block and combined with pistons made from aluminum. Crankshaft, camshaft and intake/exhaust valves are made of steel, assembled to cylinder blocks and cylinder heads made of aluminum.

Since the coefficient of thermal expansion are different between aluminum and steel, clearance deviates according to temperature fluctuation.

At SPOON SPORTS, we take pride in assembling all our engines in a cleanroom, temperature controlled to maintain an environment for optimum clearance management during assembly.

Precision components are assembled in a constant environment by our skilled engine builders. We look forward to delivering the true performance of the Honda engine to our customers!

Taxes:

TVA / IVA / VAT: All import taxes (TVA / IVA / VAT) are included in our pricing. No other taxes will be charged to you during delivery!

TVA / IVA / VAT: All import taxes (TVA / IVA / VAT) are included in our pricing. No other taxes will be charged to you during delivery!

Shipping:

This product will be shipped from our Japanese Warehouse to our European Warehouse and redistributed in Europe!

This product will be shipped from our Japanese Warehouse to our European Warehouse and redistributed in Europe!

This part fits:

K20C1 | 2000cc | DOHC | 16v | TC | I4

K20C1 | 2000cc | DOHC | 16v | TC | I4

Related Products

Spoon - Blue Printed Engine - Honda L15C

€14.144,40

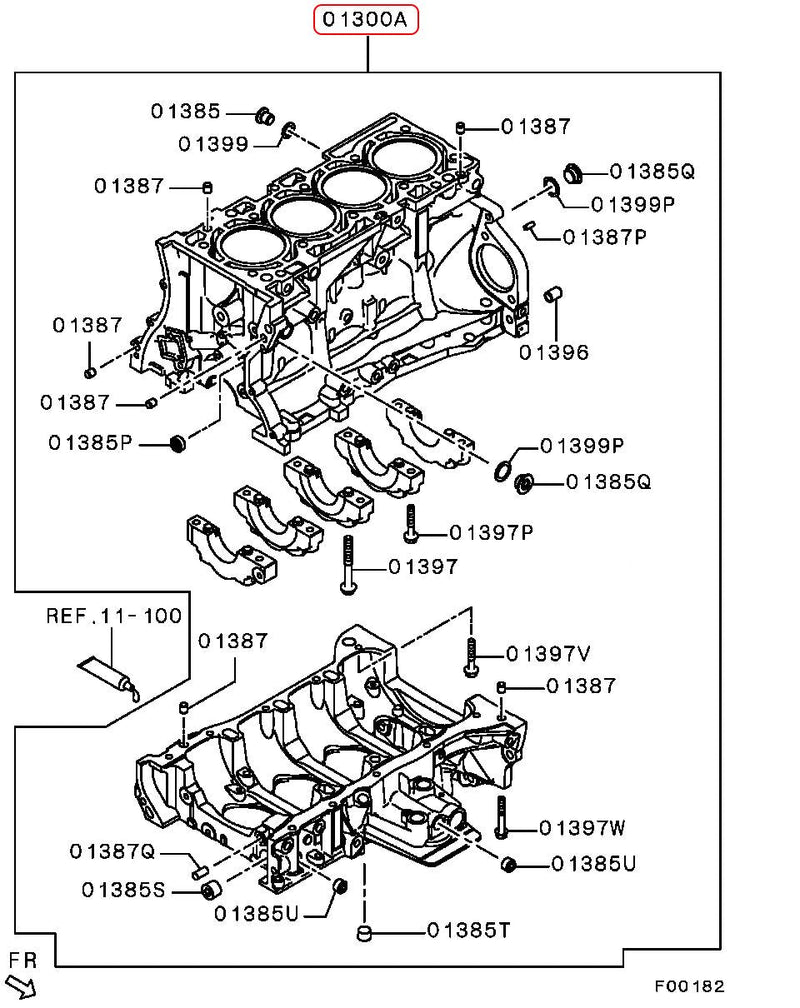

OEM Mitsubishi - Engine Block Assy - Mitsubishi 4B11T

€2.708,00 €2.592,10

Spoon - Blue Printed Engine - Honda K Series

€14.895,00 €13.505,80

Spoon - Blue Printed Engine - Honda K Series

€14.144,40

Spoon - Blue Printed Engine - Honda K Series

€14.144,40

Spoon - Blue Printed Engine - Honda F22C

€16.892,40

Spoon - Blue Printed Engine - Honda F20C

€16.892,40

Spoon - Blue Printed Engine - Honda F20C

€16.892,40